info@asthaana.com

Detailed drawings that show the precise locations and dimensions of MEP components, ensuring they fit seamlessly within the building structure.

These drawings provide exact details of the individual pipes or ducts and their fittings, as well as information on their fabrication and installation.

3D models used to visualize and coordinate the MEP systems in the context of the entire building. These models aid in detecting clashes and optimizing the layout.

Comprehensive lists of materials required for the fabrication and installation of MEP components.

Autodesk Revit

Autodesk AutoCAD

Revizto

Fabrication CAMduct

Autodesk Navisworks

Graphisoft Archicad

SysQue

BIMcollab

Autodesk ReCap

Every project starts with adjusting its own database. At this first stage, we take into account all data provided by customers concerning materials, connections, insulation, and services types of ducts and pipes to model HVAC components in the most efficient way.

.webp)

Using submittals information, we download all necessary families from official manufacturer websites or create these families ourselves if they aren’t available on the internet. This approach can guarantee 100% model conformity to clients' requirements.

.webp)

We can offer modeling primary coordination of MEP systems “from scratch” by design drawings for such disciplines: HVAC, Plumbing, Electrical, Fire Protection.

.webp)

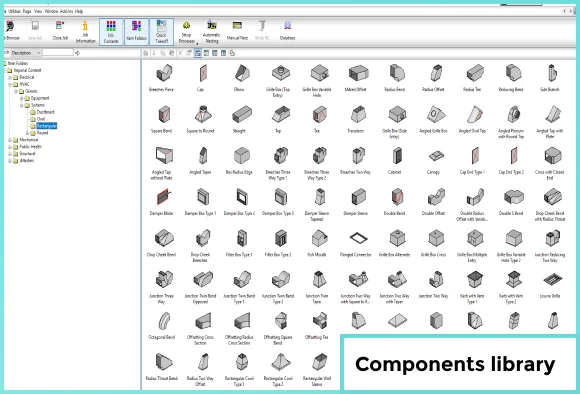

Using CAMduct or SysQue software our team are capable to implement Fabrication of MEP systems according to technical information provided by customer. HVAC and Fire Protection are our main directions in this field.

.webp)

During the drawings creation process we always try to represent all required information about MEP components and optimize them to make drawings not only informative but convenient in usage.

.webp)

At this stage we have two main objectives: find and solve all interdisciplinary clashes which occur, optimize MEP systems routing to achieve a balance between system efficiency and its moderate cost.

.webp)

The final stage of our work is Spools creation. We provide to our clients spool maps and worksheets, that consist of all demanded information for duct and pipe manufacturing.